Shanghai OE always adheres to the business philosophy of honesty and customer first, focusing on quality, pursuing excellence, and is committed to creating the world's most competitive electric vehicle power train system and promoting the development of the electric vehicle industry. We sincerely look forward to cooperating with more foreign customers.

|

parameters |

EPT2-125 |

|

operating voltage range(V) |

240-460 |

|

Peak power(kW) |

125 |

|

Rated power(kW) |

60 |

|

Motor peak torque(Nm) |

280 |

|

Motor rated torque(Nm) |

125 |

|

Motor rated speed(rpm) |

12000 |

|

Gearbox ratio |

9.11 |

|

Peak wheel speed(rpm) |

1317 |

|

Peak wheel torque(Nm) |

2550 |

|

Rated wheel torque(Nm) |

1138 |

|

Maximum system efficiency |

>91% |

|

MOQ |

100pcs |

1. Strong power, peak torque reaches 223N.m

2. The controller is small and lightweight (5L, 5KG)

3. High EMC grade design (Class 4)

4. High system efficiency, up to 95% or more

1. High integration.

2. High product efficiency.

3. Strong climbing ability: The gradeability reaches 25%, which is especially suitable for mountain driving.

4. The product is mature and has been widely recognized by the market.

5. The weight is reduced by 100kgs compared to the direct drive system, and the torque density is 78% higher than that of the direct drive system.

6. Occupies less space and can be used in low floor designs.

7. The feedback braking system can recover 100% torque and reduce energy consumption by 10% compared with direct drive.

8. High safety and reliability, can integrate ASR and ESP functions.

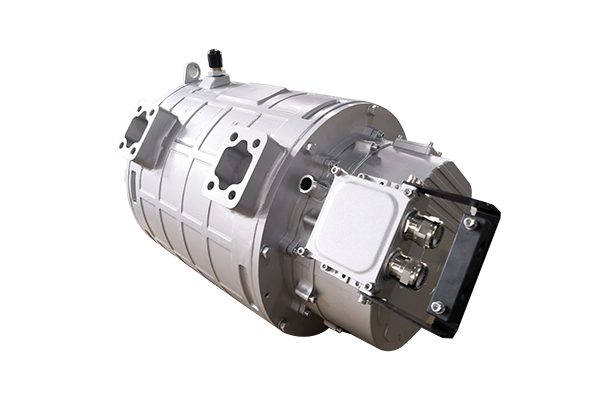

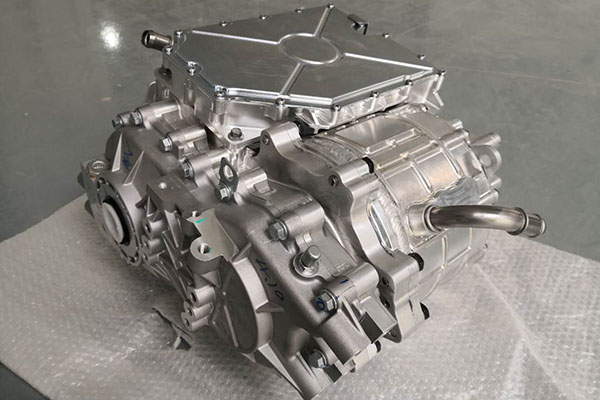

integrated design concept of motor,motor controller, and gearbox, reaching the international first-class design level.

2. Better cost

The motor and controller are integrated together, which can reduce the length of the three-phase wire and the three-phase wire connectors and water pipes; It can reduce the subassembly process of the bus factory.

3. Efficient assembly and debugging

Through the integrated design, the assembly stations of the production line of auto companies are reduced and work efficiency is improved.

|

ITEMS |

Parameter |

|

DC voltage platform(V) |

540 |

|

rated power(kw) |

120 |

|

Peak power(kw) |

200 |

|

Rated torque(N.m) |

1300 |

|

Peak torque(N.m) |

2800 |

|

Rated speed(rpm) |

880 |

|

Peak speed(rpm) |

2500 |

|

Protection level |

IP68 |

|

Cooling form |

Water cooling |

1. It is generally operated in the city or suburbs, with good road conditions, and it runs around 150Km every day; 2. The driving speed is mostly between 25 ~ 40Km / h, and the configuration of charging equipment is more convenient; 3. Road conditions are congested and idling time is long, which greatly reduces urban pollution compared with traditional fuel vehicles.

2.Real-time measurement and calculation of vehicle weight: accuracy 10%; Real-time slope measurement and calculation:

3.Shift timing and shift time: refer to vehicle weight, slope, driver's intention (throttle system)The depth and speed of the pedal), acceleration and other dynamic shift point adjustment, change Block time <0.7s;

4.Lower energy consumption: digital intelligent electronically controlled shifting system for more precise shifting; higher performance Energy-efficient door drive technology, lower switching loss;

|

Rated power 220KW |

Rated speed: 1400rpm |

|

Peak power: 350KW |

Battery voltage: 614V |

|

Rated torque: 1500N.m |

Max torque: 2500 N.m |

|

Rated current: 290A |

Max speed: 3000rpm |

|

Rated frequency: 140Hz |

Rated efficiency: big than 96% |

|

Protection level: IP67 |

Isolation class: H |

|

Line back EMF rms@1000rpm: 235V |

Peak current: 630A |

|

Weight: |

278kg

|

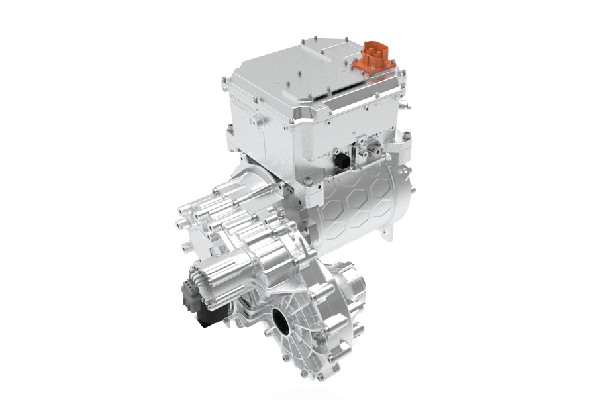

Highly integrated three-in-one drive assembly system.

The amount is reduced by 15%, and the cost is saved by 20%.

Scalable modular platform to flexibly match different customers.

Demand, greatly shorten the product development cycle and save costs.

Frequency conversion and multi-vector decoupling control algorithms, effectively.

Machine dynamic response and NVH characteristics.

Perfect fault diagnosis and safety monitoring mechanism, effective.

Ensure the high pressure safety, torque safety and high temperature safety of the whole vehicle MOQ:100pcs

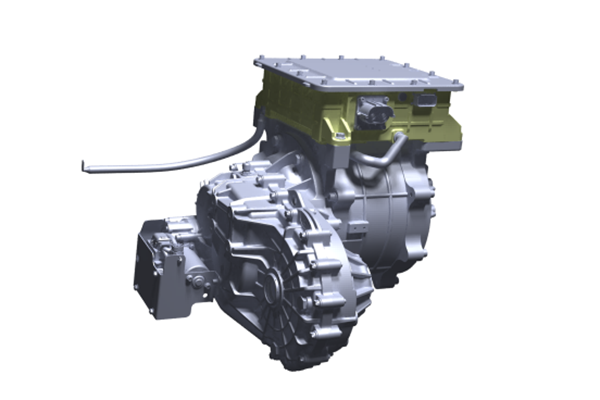

• Highly integrated three-in-one drive assembly system, product heavy.

The amount is reduced by 15%, and the cost is saved by 20%.

• Scalable modular platform to flexibly match different customers.

Demand, greatly shorten the product development cycle and save costs.

• Frequency conversion and multi-vector decoupling control algorithms, effectively.

Machine dynamic response and NVH characteristics.

• Perfect fault diagnosis and safety monitoring mechanism, effective.

Ensure the high pressure safety, torque safety and high temperature safety of the whole vehicle.

Highly integrated three-in-one drive assembly system, product heavy.

The amount is reduced by 15%, and the cost is saved by 20%;

Scalable modular platform to flexibly match different customers.

Demand, greatly shorten the product development cycle and save costs.

Frequency conversion and multi-vector decoupling control algorithms, effectively.

Machine dynamic response and NVH characteristics.

Perfect fault diagnosis and safety monitoring mechanism, effective.

Ensure the high pressure safety, torque safety and high temperature safety of the whole vehicle.

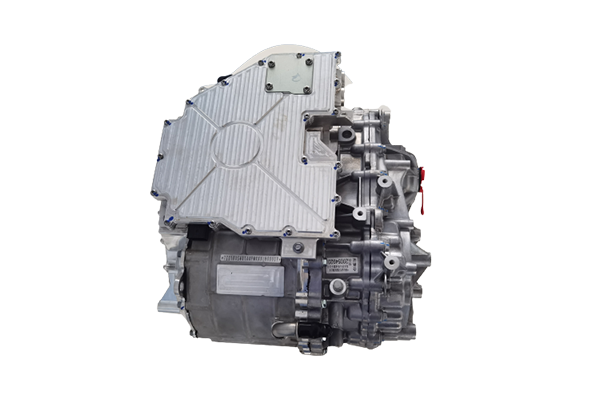

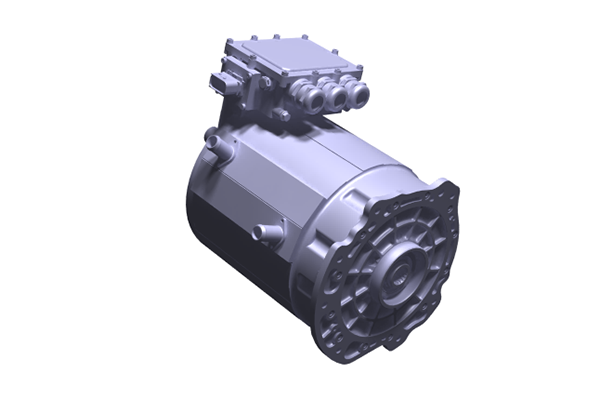

1) Small size, high energy. The motor weighs about 45Kg, but the peak power reaches 120KW;

2) The measured performance is perfect. The highest efficiency of the assembly system is 94.8%, and the high efficiency area >85% accounts for >85%;

3) The motor and electronic control match perfectly. The peak torque is reached under the condition of electronically controlled peak current, and the design is perfect!

4) It can be used for small cars, small trucks, and marine motors.

5) Permanent magnet motor, high efficiency.

|

Model |

TZ204XSB12 |

No. |

|

|

Coil connection |

Y |

Phase |

Three-phase |

|

Working system |

S9 |

Rated voltage(VAC) |

220 |

|

Continuous power(KW) |

63 |

Peak power(KW) |

120 |

|

Continuous torque(N.m) |

150 |

Peak torque(N.m) |

250 |

|

Rated speed(rpm) |

4000 |

Maximum speed(rpm) |

12000 |

|

Stall torque(N.m) |

250 |

Stalling duration(s) |

10 |

|

Insulation class |

H |

Protection level |

IP67 |

|

quality |

45KG |

Dimensions |

L310X D241 |

|

cooling method |

Liquid cooling |

Cooling water flow(L/Min) |

>8 |

|

ITEM |

The standard configuration |

|

Chassis curb weight (Kg) |

7000 |

|

Maximum total mass (Kg) |

18000 |

|

Drive form |

4×2 |

|

Length (mm) |

11987 |

|

Width (mm) |

2500 |

|

Height (mm) |

1448 |

|

Wheelbase (mm) |

6500 |

|

Track front / back (mm) |

1940/1860 |

|

Front / rear suspension (mm) |

2060/3427 |

|

Minimum ground clearance (mm) |

≥300 |

|

Approach / departure angle (°) |

14/13 |

|

Full load maximum climbing |

≥15%(With 20% configuration) |

|

Minimum turning diameter (m) |

18 |

|

Maximum speed (km / h) |

80 |

|

Power Battery |

6C + 4G box, battery 315KWh, |

|

motor |

Disc hub ICS200K motor |

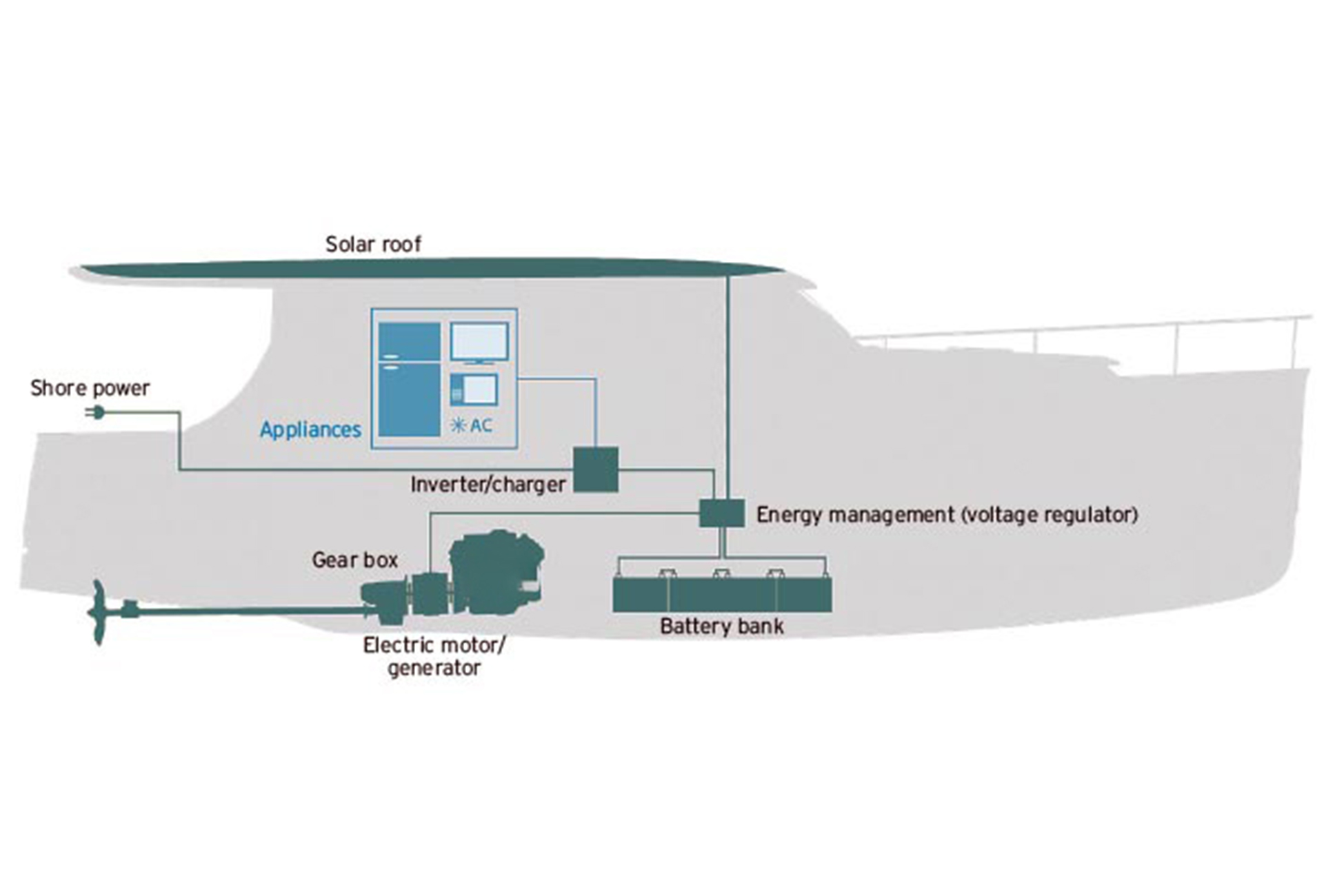

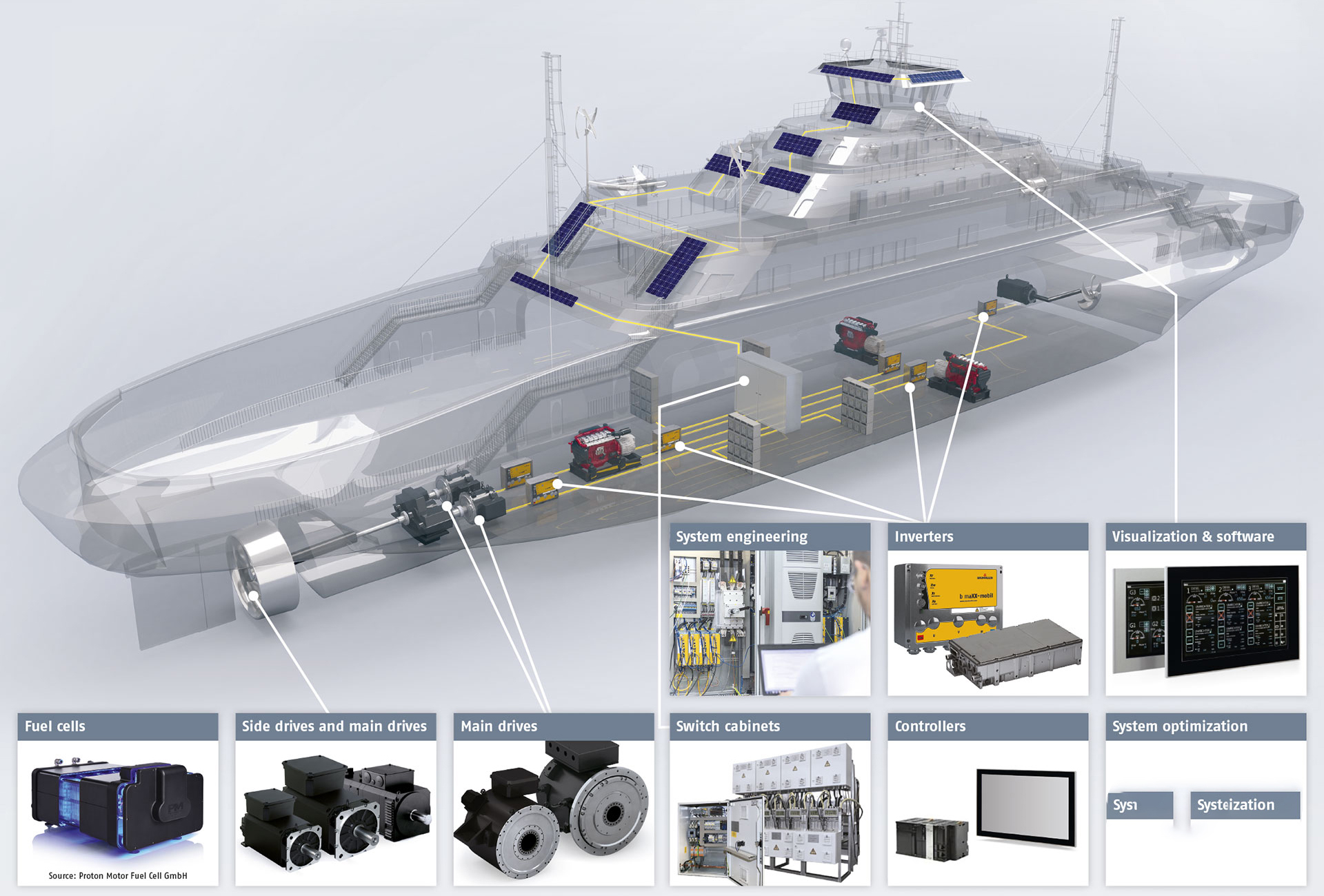

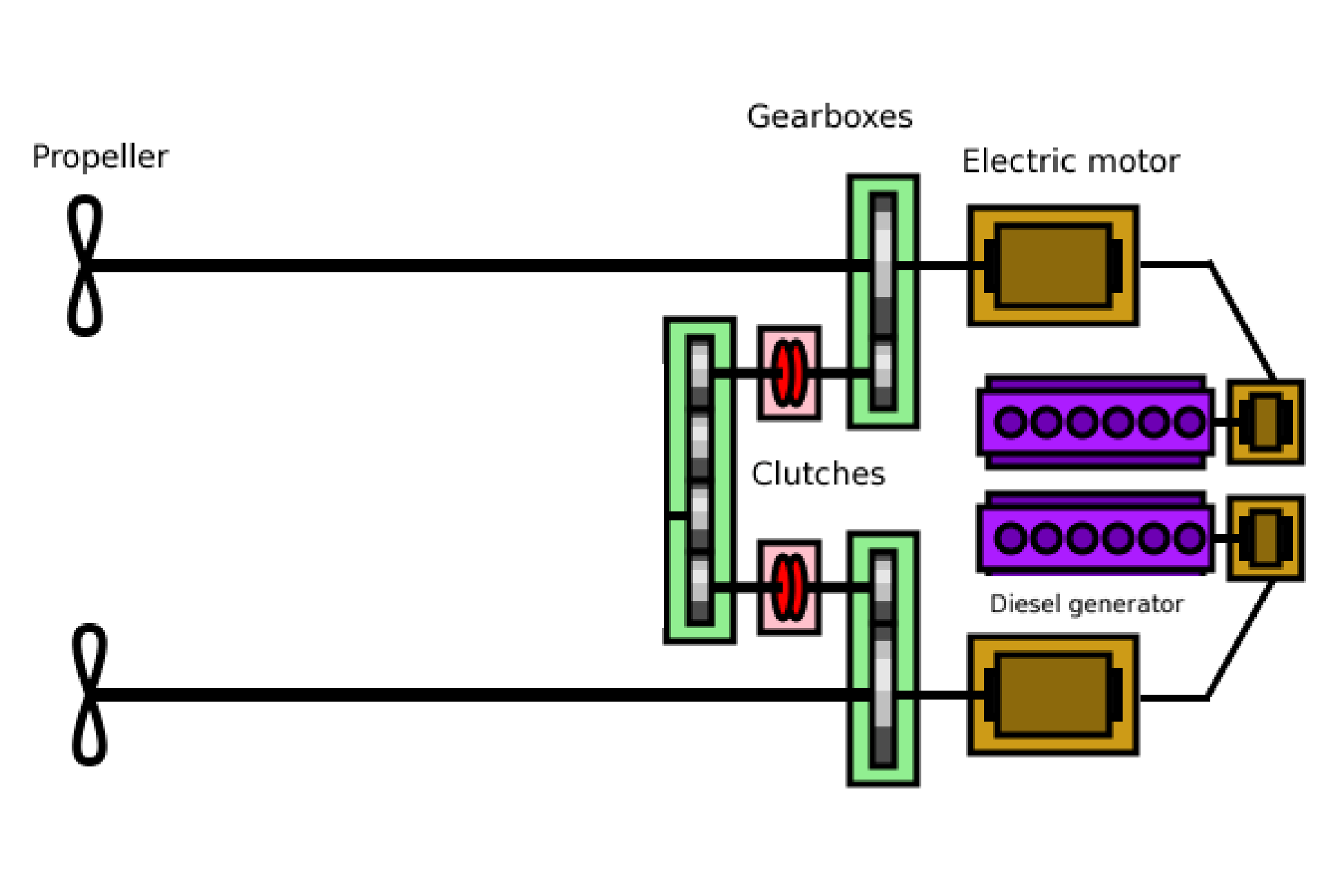

We are supplying a new-energy power propulsion system using energy storage batteries as energy, and is in a leading position in both domestic technology and the market.

We are supplying new-energy power propulsion system using energy storage batteries as energy, and is in a leading position in both domestic technology and the market.

Pure electric transportation (rescue) ship will soon become a standard ship to promote application. 19.3 m long, 4.5 m wide, Main suppliers:

AESS lithium battery system

DC600 DC power distribution system

MLC-DC intelligent bus switch

DPM permanent magnet motor 2x200kW

EMS energy management system

PCS propulsion control system.

1) Mainly provide driving power for 10-12m direct drive vehicles.

2) Modular design of software platform, complete diagnosis strategy.

3) Wide speed range, excellent field weakening performance, support background monitoring, CAN communication.

4) The control method adopts rotor field-oriented vector control.

5) Rotation speed is collected by resolver.

6) With protection and alarm functions for over current, over voltage, under voltage, over temperature, overload, locked rotor, short circuit between phases, and encoder disconnection.

|

|

Physical integration |

Magnetic integration |

|

Technical approach |

Independent operation |

Shared power transistors, |

|

Cooling channel |

2D |

3D |

|

volume(L) |

5.3 |

3.83 |

|

weight(kg) |

6.6 |

5 |

|

technical difficulty |

low |

high |

Bus charging stations, operating charging stations

Product overview

• Output voltage up to 1000V (module optional)

• New self-developed TCU+CCM control system

• Constant power range 300--1000V (module optional)

• Air cooling cooling

• Modular combination design

|

Rated/Peak Power: |

50/100kw |

|

Rated/Peak Torque: |

145/290N.m |

|

Peak Speed: |

9600rpm/min |

|

Voltage: |

237VAC 3Phase |

|

Protection Level: |

IP67/H |

|

Cooling methord: |

Liquid cooling |

|

Rated/Peak Capacity: |

65/137KVA |

|

Battery Cell: |

173Ah |

|

Battery Capacity: |

65.17kWh |

-

Motor production video

-

Motor calibration and function test

-

Test:Washboard Pavement

-

Motor Test

-

Test:Belgian Pavement

-

Bench test

-

Assemble offline detection

-

Assemble group test

Products can be customized: develop according to the parameters required by customers, and we can verify that the products meet customer requirements.

The product is used in electric vehicles (cars, trucks, buses, mining carts,), Electric ships (boats, yachts, big ships), Electric engineering machinery, to replace the traditional gasoline engines, diesel engines, and play a role in energy saving and environmental protection.

One prototype can be sold, and orders are required after mass production. Generally, 10-100 sets can be ordered.

- Room 205, Building#2, Zhangmu Inudstrial park, No. 2328, Chunshen Road, Minghang, Shanghai

- Tel: 86-21-54381147

- Mobile: 86-13611656385

- E-mail: henry.liao@oe-autoparts.com

- Skype/Whatsapp: 0086-13611656385

- Facebook: https://www.facebook.com/Shanghai-OE-Industrial-110458214104273/